In the realm of scientific advancement, high-impact inorganic catalysts have been game changers, revolutionising industries from pharmaceuticals to environmental protection. These catalysts, known for their ability to accelerate chemical reactions without being consumed, have roots tracing back to the early 20th century when their potential first began to unfold. Today, they stand at the forefront of sustainable chemistry, offering solutions that are not only efficient but also environmentally friendly. This post delves into the world of these powerful catalysts, exploring their significance, applications, and the cutting-edge research that continues to push their boundaries further. Whether you’re a seasoned scientist or simply curious about the latest in technology and sustainability, understanding the role of high-impact inorganic catalysts is key to grasping the future of innovation.

Understanding Inorganic Catalysts

Catalyst Types

Inorganic catalysts are crucial in speeding up chemical reactions without being consumed. They come in various forms, each suited for specific processes.

Homogeneous catalysts share the same phase as the reactants, often leading to uniform reaction conditions. These catalysts facilitate precise control over the reaction environment, making them ideal for delicate chemical processes.

Heterogeneous catalysts exist in a different phase than the reactants. They offer easier separation from the reaction mixture and are commonly used in industrial applications due to their robustness and reusability.

Key Materials

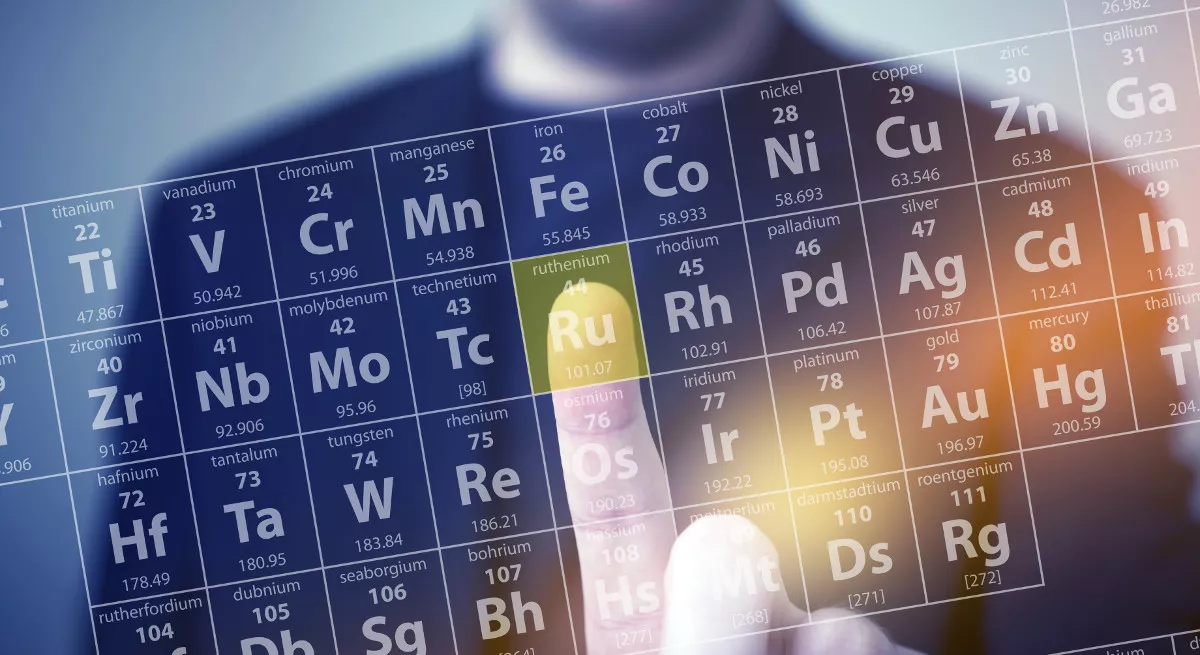

Inorganic catalysts utilize materials with unique properties to drive chemical reactions. Transition metals like platinum and palladium are widely used due to their ability to facilitate electron transfer processes. These metals serve as excellent catalysts in hydrogenation reactions, where they add hydrogen to other molecules.

Oxides of metals such as titanium dioxide are also significant, especially in photocatalysis. They harness sunlight to initiate chemical reactions, offering a green alternative to traditional energy-intensive processes.

Industrial Applications

The role of inorganic catalysts in industry cannot be overstated. They are pivotal in energy production, including the refining of crude oil into gasoline and other fuels. This process is vital for meeting the world’s energy demand efficiently.

In the manufacturing sector, inorganic catalysts are essential for producing polymers and plastics. They help in polymerization reactions, transforming small molecules into long-chain polymers used in various products from packaging to automotive parts.

Environmental Impact

Inorganic catalysts also play a significant role in environmental protection. They are key in reducing harmful emissions from vehicles and industrial plants by catalyzing the breakdown of pollutants into less harmful substances.

Moreover, they enable green chemistry practices by making chemical processes more efficient and less wasteful. This includes developing renewable energy sources and creating more sustainable manufacturing methods.

Types of Inorganic Catalysts

Metal Oxides

Metal oxides serve as powerful catalysts in various chemical reactions. They are particularly effective in oxidation processes. For example, titanium dioxide is widely used in the degradation of pollutants. It breaks down harmful substances when exposed to UV light.

This type of catalyst is durable and can withstand high temperatures. Its stability makes it a preferred choice for industrial applications.

Zeolites

Zeolites are microporous, aluminosilicate minerals that offer unique advantages as catalysts. They are known for their selective adsorption properties. This means they can pick out specific molecules from a mixture, making them ideal for refining petroleum and petrochemical synthesis.

They have a well-defined structure with uniform pore sizes. This allows for precise control over the chemical process, leading to higher yields and purity of the final product.

Transition Metals

Transition metals like palladium, platinum, and rhodium are critical in catalysis. They play a key role in hydrogenation reactions, where hydrogen is added to other compounds. These metals can also facilitate carbon-carbon bond formation, essential in creating complex organic molecules.

Their ability to easily donate and accept electrons makes them versatile catalysts in organic synthesis. However, their high cost often necessitates the development of recovery and recycling methods.

Enzyme Mimics

Inorganic catalysts designed to mimic enzymes offer a bridge between biological and chemical catalysis. These catalysts can perform highly selective reactions at ambient temperatures and pressures, similar to natural enzymes.

They are used in biosensing, environmental monitoring, and synthesizing pharmaceuticals. The design of enzyme mimics focuses on achieving high specificity and efficiency while being more stable than their organic counterparts.

Importance in Chemical Processes

Energy Efficiency

Inorganic catalysts play a crucial role in enhancing energy efficiency in chemical processes. They accelerate reactions, reducing the energy required to achieve desired outcomes. This not only cuts down on costs but also minimizes environmental impact.

These catalysts allow for reactions at lower temperatures and pressures. Industries save significantly on heating and cooling, which are major energy consumers. The reduction in fossil fuel consumption is a direct benefit, contributing to lower carbon footprints.

Environmental Impact

The use of inorganic catalysts directly influences the environmental footprint of chemical manufacturing. By enabling more efficient reactions, they reduce the generation of waste products. This is pivotal in industries striving for green chemistry principles.

They assist in the development of cleaner processes by facilitating reactions that produce fewer byproducts. This leads to less chemical waste needing disposal or treatment. In cases where toxic substances were traditionally produced, catalysts can offer alternative pathways that are safer for the environment.

Economic Benefits

The economic implications of adopting high-impact inorganic catalysts are profound. By streamlining processes and reducing energy requirements, companies can achieve substantial cost savings. These savings come from lower raw material needs and reduced energy consumption.

Moreover, catalysts often allow for the use of cheaper, more abundant starting materials without compromising product quality. This flexibility can lead to more competitive pricing and higher profit margins for manufacturers.

Product Quality

Inorganic catalysts are key to achieving high product quality in various chemical syntheses. They provide selectivity, ensuring that the desired product is obtained with minimal impurities. This specificity is critical for pharmaceuticals and fine chemicals, where purity is paramount.

They also support consistent product performance by maintaining reaction conditions stable. This reliability is essential for industries where product standards cannot be compromised.

Innovation Driver

Catalysts act as drivers of innovation within the chemical sector. They open doors to new chemical reactions that were previously unfeasible, leading to novel materials and compounds. This has far-reaching implications for drug development, materials science, and beyond.

Their role in sustainability initiatives cannot be overstated. By offering pathways to environmentally benign processes, they contribute to the development of renewable energy sources and biodegradable materials.

Properties and Mechanisms

Surface Area

High-impact inorganic catalysts boast a large surface area. This trait is crucial for facilitating reactions. A larger surface means more sites for reactants to attach and interact.

Catalysts like zeolites have frameworks that increase their surface area. This makes them highly effective in processes such as cracking in the petroleum industry. They break down large hydrocarbon molecules into smaller, more useful ones.

Active Sites

The effectiveness of inorganic catalysts hinges on their active sites. These are specific areas where reactions occur. The nature and arrangement of these sites dictate the catalyst’s selectivity and activity.

For instance, heterogeneous catalysts offer distinct active sites on their surfaces. This allows for selective reactions, crucial in creating pure products. Metals like platinum and palladium are known for their high number of active sites, making them valuable in catalytic converters for reducing vehicle emissions.

Catalytic Efficiency

Catalytic efficiency depends on how well a catalyst facilitates a reaction without being consumed. Inorganic catalysts often excel here, offering speed and specificity without degradation.

Their efficiency can be seen in the Haber process. Here, iron-based catalysts enable the synthesis of ammonia under manageable conditions. This process is vital for fertilizer production, showcasing the direct impact of catalyst efficiency on global food supply.

Reaction Mechanisms

Understanding the reaction mechanisms of inorganic catalysts is key to optimizing their performance. These mechanisms vary widely, from simple adsorption and desorption to complex multi-step processes.

For example, photocatalysts like titanium dioxide utilize light energy to drive chemical reactions. They’re instrumental in environmental cleanup efforts, breaking down pollutants into less harmful substances.

Stability and Durability

Inorganic catalysts are often prized for their stability and durability under harsh conditions. Their resistance to high temperatures and corrosive environments makes them ideal for industrial applications.

Silica and alumina-based catalysts, used in oil refining, exemplify this durability. They maintain their structure and activity even after prolonged exposure to extreme conditions.

Commonly Used Inorganic Catalysts

Platinum Group

Platinum and its group members, like palladium and rhodium, are widely recognized for their roles in catalysis. They facilitate chemical reactions without undergoing permanent changes themselves. These metals are particularly effective in hydrogenation processes and in vehicle exhaust systems to reduce harmful emissions.

In the automotive industry, platinum-based catalysts convert toxic gases from car exhaust into less harmful substances. This process is vital for meeting environmental regulations.

Transition Metals

Transition metals such as iron, copper, and cobalt serve as catalysts in various industrial applications. They are crucial for the synthesis of ammonia in the Haber process. This reaction is essential for producing fertilizers that support global agriculture.

Iron catalysts help in the production of ammonia by combining nitrogen and hydrogen gases under high pressure and temperature. This demonstrates their importance in sustaining food production worldwide.

Zeolites

Zeolites are microporous aluminosilicates with a unique structure that makes them excellent catalysts in petrochemical industries. They are used to crack heavy petroleum molecules into gasoline, diesel, and other valuable chemicals.

Their high surface area allows zeolites to act as efficient molecular sieves. This property is beneficial in refining crude oil into more usable forms.

Enzyme Mimics

Scientists have developed inorganic compounds that mimic the action of enzymes. These enzyme mimics are designed to catalyze reactions under conditions where natural enzymes would be unstable.

They play a pivotal role in biomedical research and drug development by facilitating biochemical reactions at lower temperatures and pressures compared to traditional methods.

Acid-Base Catalysts

Certain inorganic compounds function as acid or base catalysts depending on their composition. Examples include alumina (Al2O3) and silica (SiO2), which are used in various chemical syntheses and petroleum refining processes.

These catalysts promote reactions by providing acidic or basic sites for reactants to interact more effectively. Their use enhances the efficiency of chemical manufacturing processes.

Advanced Catalytic Applications

Energy Production

Renewable energy technologies often rely on catalysts to improve efficiency. Inorganic catalysts play a critical role in hydrogen production and fuel cell technologies. They help split water into hydrogen and oxygen through electrolysis, a process essential for clean energy.

These catalysts also enhance the performance of fuel cells by speeding up the electrochemical reactions. This leads to more efficient electricity generation from hydrogen. The use of robust inorganic catalysts can significantly lower the cost of renewable energy technologies.

Pollution Control

Catalysts are indispensable in reducing environmental pollution. They are at the heart of catalytic converters in vehicles, which reduce harmful emissions. These converters transform toxic gases like carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful substances such as nitrogen, carbon dioxide, and water vapor.

In industrial settings, inorganic catalysts help manage waste by treating pollutants in exhaust gases. This ensures cleaner air and adherence to environmental regulations. Their high stability and effectiveness make them ideal for long-term applications in pollution control.

Chemical Synthesis

The pharmaceutical and chemical industries benefit greatly from advanced catalysis. Inorganic catalysts facilitate complex reactions under milder conditions, increasing yield and reducing energy consumption. They enable the efficient synthesis of drugs, plastics, fertilizers, and other chemicals.

These catalysts offer selectivity, allowing chemists to target specific reaction pathways. This minimizes by-products and waste, making processes more sustainable. Their versatility and efficiency open up new possibilities in material science and chemical engineering.

Water Purification

Access to clean water is a global challenge. Inorganic catalysts contribute to water purification technologies by breaking down pollutants at the molecular level. They assist in removing organic compounds, heavy metals, and other contaminants from water sources.

This catalytic process not only ensures safer drinking water but also protects aquatic ecosystems from pollution. By leveraging these catalysts, communities can implement cost-effective and efficient water treatment solutions.

Recent Breakthroughs in Catalysis

Metal-Organic Frameworks

Metal-organic frameworks (MOFs) have emerged as a game changer in the field of catalysis. These porous materials combine metal ions with organic ligands to create structures with high surface areas. They excel in gas storage, separation, and catalytic applications.

Researchers have fine-tuned MOFs to target specific reactions. This has led to unprecedented efficiency in processes like carbon dioxide reduction and methane conversion. The versatility of MOFs allows for tailor-made catalysts that meet industrial demands more effectively than ever before.

Single-Atom Catalysts

Single-atom catalysts (SACs) represent a significant leap forward. They maximize the utility of precious metals by dispersing them as individual atoms on supports. This approach enhances catalytic activity and selectivity while minimizing material use.

SACs have shown remarkable results in fuel cell technology, particularly in oxygen reduction reactions. Their high efficiency and durability make them ideal for clean energy applications. Researchers continue to explore SACs for broader uses, including organic synthesis and pollution control.

Photocatalysis Advances

Recent years have seen a surge in photocatalytic technology developments. Scientists have engineered materials that harness sunlight to drive chemical reactions. This method is not only sustainable but also cost-effective, offering a green alternative to traditional energy-intensive processes.

Titanium dioxide (TiO2) remains a popular choice due to its stability and abundance. However, novel materials like graphitic carbon nitride (g-C3N4) and perovskites are gaining traction. These advancements open up new pathways for water purification, hydrogen production, and air cleaning.

Enzyme Mimics

Enzyme mimics stand out for their ability to catalyze reactions under mild conditions. These synthetic compounds imitate nature’s enzymes, offering an environmentally friendly approach to catalysis. They’ve become crucial in pharmaceutical manufacturing, where precision and mild reaction conditions are paramount.

Innovations in enzyme mimicry have led to catalysts that operate with high specificity and low energy input. This breakthrough is pivotal for developing new drugs and biodegradable materials.

Industrial Applications

Energy Sector

The energy industry benefits greatly from high-impact inorganic catalysts. They play a crucial role in fuel refinement and the production of renewable fuels. Catalysts improve the efficiency of converting crude oil into gasoline, diesel, and other essential products.

In renewable energy, catalysts are key for producing biofuels from plant materials. They help break down complex molecules into simpler, usable forms of energy. This process makes alternative fuels more viable and lessens our reliance on fossil fuels.

Chemical Manufacturing

In chemical manufacturing, inorganic catalysts are indispensable. They speed up reactions in the production of plastics, fibers, and rubbers. This acceleration is vital for meeting global demand efficiently.

Catalysts also enable more sustainable chemical processes by lowering energy requirements and reducing waste. For example, they are used in making polymers more environmentally friendly. This shift towards greener practices is crucial for the industry’s future.

Environmental Protection

High-impact inorganic catalysts have a significant role in environmental protection. They are used in removing pollutants from industrial emissions before they reach the atmosphere. Catalysts convert harmful gases like carbon monoxide and nitrogen oxides into harmless substances.

Moreover, catalysts are employed in water treatment plants to break down toxic chemicals. This ensures cleaner water returns to natural bodies or is reused in industrial processes. Their application in this area highlights their importance beyond economic benefits.

Pharmaceutical Industry

The pharmaceutical sector relies on catalysts for drug synthesis and production. Catalysts allow for the creation of complex molecules needed in medications. They make these processes faster and more cost-effective.

Catalysts also contribute to developing new drugs by enabling novel chemical reactions. This capability is critical for advancing medical treatments and improving public health outcomes.

Laboratory Applications

Catalyst Testing

High-impact inorganic catalysts undergo rigorous testing in laboratories before they see industrial use. Scientists assess their efficiency and stability under various conditions. This process is crucial for understanding how these catalysts behave in real-world applications.

They subject the catalysts to a series of reactions to measure their activity levels. The goal is to find catalysts that offer high performance with minimal degradation over time. Researchers also examine how different environmental factors, like temperature and pressure, affect the catalysts’ effectiveness.

Material Synthesis

In labs, inorganic catalysts play a pivotal role in the synthesis of new materials. These catalysts help in creating polymers, ceramics, and other composite materials with enhanced properties.

The use of catalysts in material synthesis allows for more precise control over the end product’s molecular structure. This precision leads to materials with specific characteristics, such as increased strength or improved electrical conductivity. Labs often explore novel catalysts to push the boundaries of what’s possible in material science.

Environmental Remediation

Laboratories also use high-impact inorganic catalysts for environmental remediation projects. These catalysts can break down pollutants into less harmful substances, making them invaluable in efforts to clean air and water.

One common application is in the treatment of industrial wastewater. Catalysts accelerate the breakdown of toxic chemicals, ensuring safer discharge into the environment. They are also used in air purifiers to remove hazardous gases from indoor environments.

Energy Conversion

Inorganic catalysts are key to developing renewable energy technologies in lab settings. They are essential for processes like water splitting and carbon dioxide reduction, which are at the heart of sustainable fuel production.

Scientists rely on these catalysts to improve the efficiency of converting sunlight into chemical energy. This research paves the way for more effective solar fuels, a critical component of our future energy landscape. By enhancing energy conversion rates, these catalysts help make renewable energy sources more viable.

Conclusion:

High-impact inorganic catalysts are game-changers, making chemical processes faster, cleaner, and more efficient. You’ve seen how they span from basic research to real-world applications, driving innovations in industries and laboratories alike. Their role in sustainability and green chemistry can’t be overstated—offering solutions to some of the most pressing environmental challenges today. By understanding types, properties, and mechanisms, you’re better equipped to appreciate their significance and potential.

Now’s the time to dive deeper. Whether you’re in research, industry, or just fascinated by chemistry, exploring advanced catalytic applications and recent breakthroughs opens up a world of possibilities. Stay curious, keep learning, and consider how you might contribute to or benefit from these exciting developments in catalysis. The future is bright with the promise of cleaner, more efficient chemical processes, thanks to high-impact inorganic catalysts.